The laboratory facility has areas and equipment for: materials storage, slurry processing, slurry characterization, tape casting, green tape characterization, punching/blanking, laminating, sintering, and fired substrate/ laminate evaluation.

Batching is typically done in grinding jars with milling media in order to prepare a homogeneous slurry. A variety of jars/media are used, such as alumina, high-alumina, zirconia, HDPE, polypropylene, etc. Batch sizes for each casting run start at a few hundred grams and can be as large as 10 kilograms. Doctor blades from 3 to 15 inches in width are used in the casting of the slurry. The doctor blade is set on a granite surface plate for tape thickness uniformity.

With continuous processing, up to several hundred linear feet of tape can be produced in a single run (batch size dependant). The cast is evaluated on-the-fly for any modifications that need to be done. The green tape is observed for defects after the cast and properties such as green tape thickness and density are measured. The tape is then sent to the customer for further evaluation. Our laboratory has equipment to test samples of each cast in order to make multi-layer laminates. Test samples can also be fired to determine the proper sintering schedule.

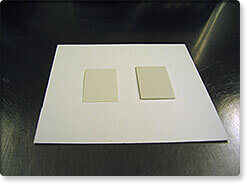

Single layer green tape blank (L) and multi-layer laminate (R)

Whether your objective is research or production oriented, Maryland Tape Casting can meet your tape requirements. Research and development is done daily to formulate and optimize tape casting recipes and process steps. Batch and continuous casts are available in sizes ranging from 0.001 – 0.100 inch thick with compositions ranging from Alumina to Zirconia and everything in between.